A few days ago I received an email from Kenny Sykes. He had received a note from a mutual friend indicating that I knew and worked with his dad, Bobby Sykes, while I was serving my time at Keith Black Racing Engines. Indeed I had. The following letter is my reply to his request. I am publishing it here because I believe it will be of interest to my readers as well as a well deserved tribute to a man of many talents whom I had the pleasure of working with during my short stint at KBRE. Thanks Bobby and thanks to you Kenny Sykes. Enjoy.

Yes, I knew and worked with your dad Bobby Sykes. Funny the way that came out, Bobby instead of Bob. I cannot remember why but I was first introduced to your dad by Keith as Bobby. And it stuck. I was always a little apprehensive about calling him Bobby because I was the youngster at the time, barely 30, and your dad could have been my dad, around 50, I guess. Before I get into our time together a little background would be in order.

In 1966 I came to Chrysler on a work/study program at the Chrysler Institute of Engineering. I soon made my way into the Race Group where I met and became friends with Pete ‘Hutch’ Hutchinson. I left Chrysler in 1969 and join Hurst to design, build and manage the AMC Javelin NASCAR race team. At the end of the season I decided to stop in California to look for some work. I stopped by Keith Black Racing Engines to see Hutch. At that time, he was working on the Trans Am program after finishing up the Indianapolis project. I’m sure I met your dad at that time but I do not recall him specifically. Pete sent me to All American Racers to interview with Dan Gurney for the upcoming Trans Am program. I got the job and proceeded to design, build and manage the program for 1970. At the end of 1970 I was floating around when I got a call from Tom Hoover, old drag race boss at Chrysler. Apparently, Chrysler had hired Harry Westlake, from England, to design a cylinder head for the then new Chrysler 426 Hemi engine. Engineering in Highland Park Michigan had run the engine with very little success and did not want to continue with its development. Hoover asked me if I would go to Keith Blacks place and continue the development of the Westlake head, designated the D5. Of course, I said yes, I was out of a job after all, and off I went to Southgate. Bob meet Bobby. Long story I know but that’s actually the short version.

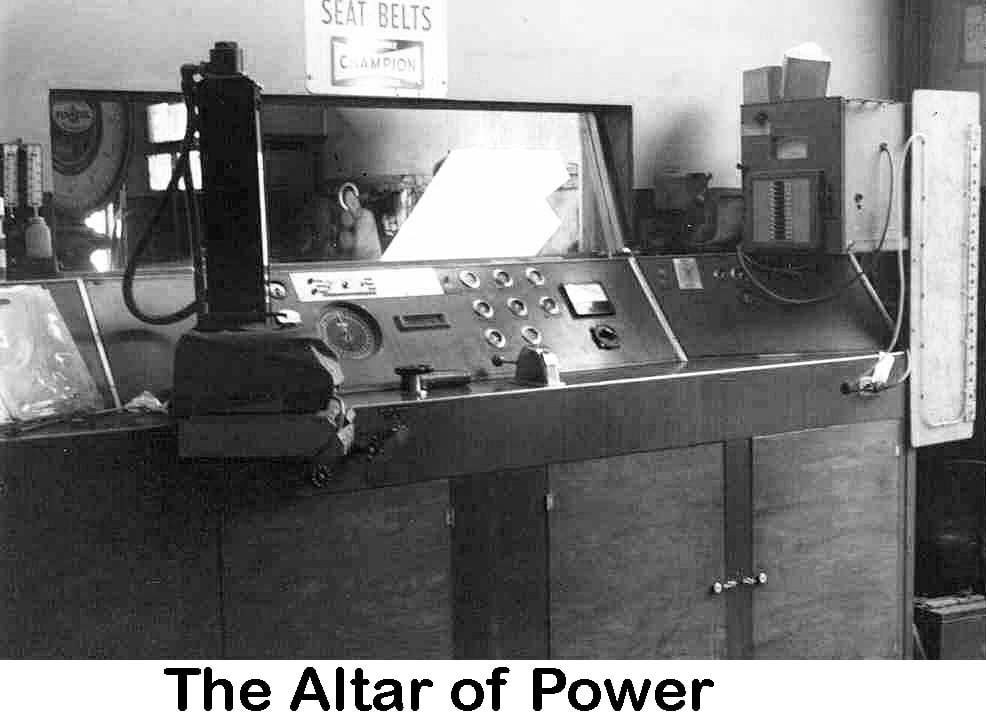

Bobby, excuse me if I continue to refer to your dad as Bobby but it’s the way I remember him. He was assigned to me, or vis versa by KB. The problem with the D5 cylinder head was that the valve guides would loosen up after a short time on the dyno. I had a few off-the-wall ideas, but your dad went right to work on the problem. In short order “we” had the problem fixed and where off and running. Which brings me to the dyno. The dyno and the dyno room were really your dad’s domain. Normally he was the main man when it came to “driving” the dyno. But somehow, I never really understood how or why, your dad sensed my desire to the “drive” the nasty beast and taught me what he knew and let me take over the chores almost from the beginning. We worked well together to say the least. The Chrysler program expanded exponentially. We were developing all of the Chrysler family of performance and race engines. The 426 hemi, 440, 383, 340, and numerous versions of the 305. Oh, and we threw in a few Mitsubishi four cylinders for variety. I usually had two of each type ready to go. As a result, we were running engines every day, probably five hours a day. There were several other engine builders that built up the Chrysler packages but your dad and I worked the most together. We, I, had a thing going. I was really into my job, but at the same time I was 30 years old. I lived in Huntington Beach and got hooked on surfing. I would go out in the early am and surf, be back home and ready to roll up to KB’s place by 8:30 or so. To get things moving at KB’s I would call your dad and tell him I was on my way and ask him to get such and such engine warmed up on the dyno and I would be there shortly. I know I wasn’t fooling anyone but he never said a world. Sometimes I would even have sea water still running out of my nose when we started the dyno runs. He would just laugh and off we’d go.

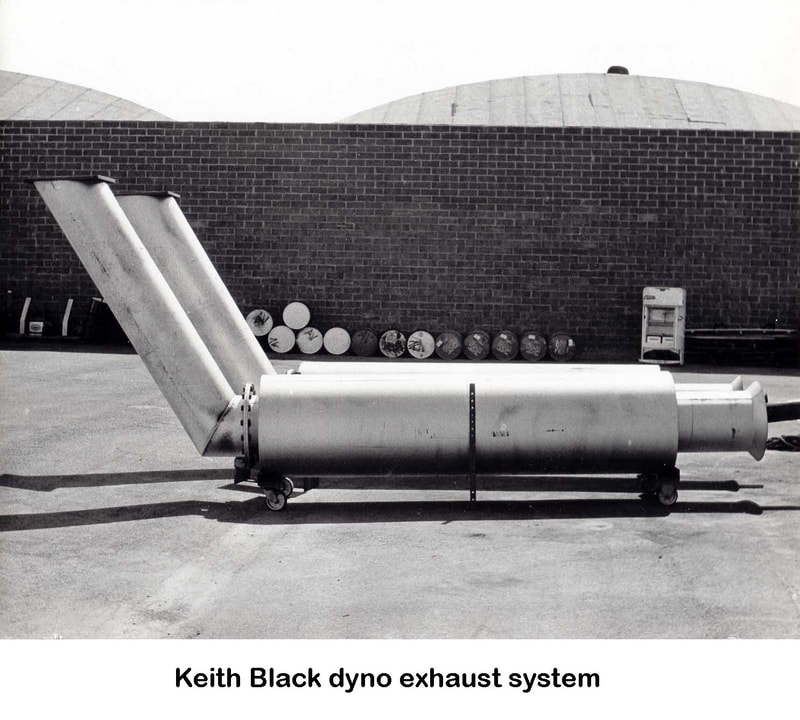

The noise from all these dyno runs became unbearable, especially for the guys working in the machine shop area. I do not know how they got away with it before. Perhaps they didn’t run as often. I thought we should have some sort of an exhaust system to contain the noise. Your dad knew exactly what we needed and how to do it. I sketched it up and you dad fabricated and welded the monstrosity together. I’ll included some photos at the end. For now, let’s just say it resembled two jet engines. But some peace was had in that little corner of Southgate. As I stated we worked on all varieties of the small block, especially the 305 version.

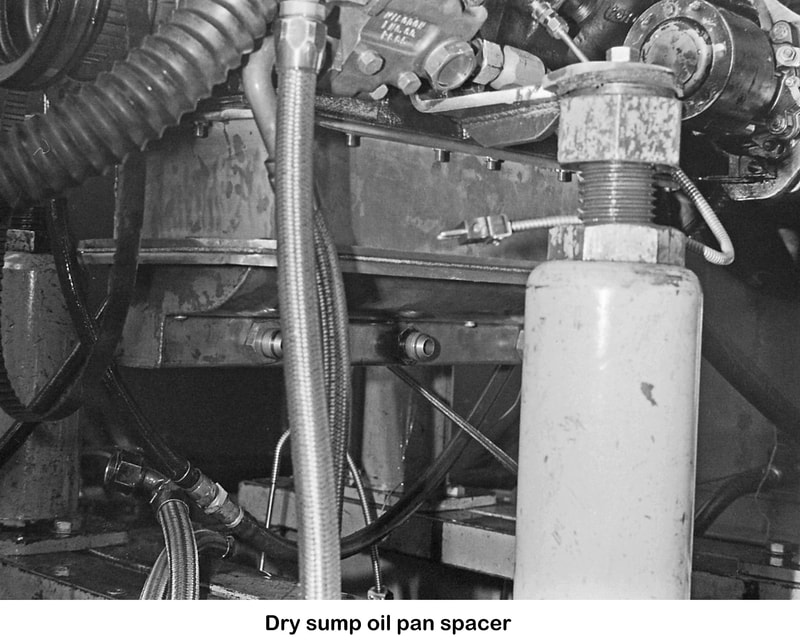

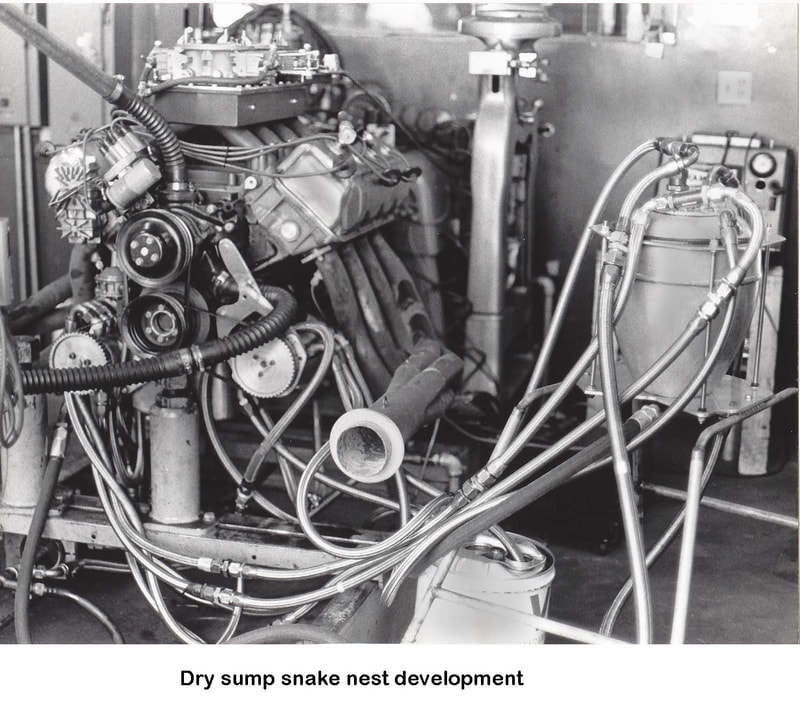

Your dad and Hutch started it with the Indy version, although it was actually 330 as I recall, but it was a small block known as the A engine. Next came the Trans Am 305 package. All the components were run through KB’s place. Then there were a number of them sent over to All American Racers for the Plymouth program and the rest were used for the Dodge program with Aerodynamics. Your dad and Hutch developed the package for the Dodges. This was in 1970. In 1971, during my tenure, came the 305 Rossi NASCAR engine. The Rossi engines were a derivative of the Trans Am package. The TA was carbureted and had a wet sump oil pan. The NASCAR version was carbureted but ran a dry sump oil pan. I specked it out but your dad did the complete build up. Part of the testing was to run a simulated NASCAR race on the dyno. I was shuffled aside for this and KB and your dad took over the dyno room command post. The engine was run at WOT for a gas tank worth of fuel. The engine was then idled to change the fuel barrel and then returned to WOT. A simulated pit stop. I just watched for this event, but your dad and KB enjoyed the hell out of being driver and pit crew. The police came by during the night to watch and then went on their way. A good time was enjoyed by all. Subsequently two 305’s where sent to Mario Rossi, Bill Rossi’s dad.

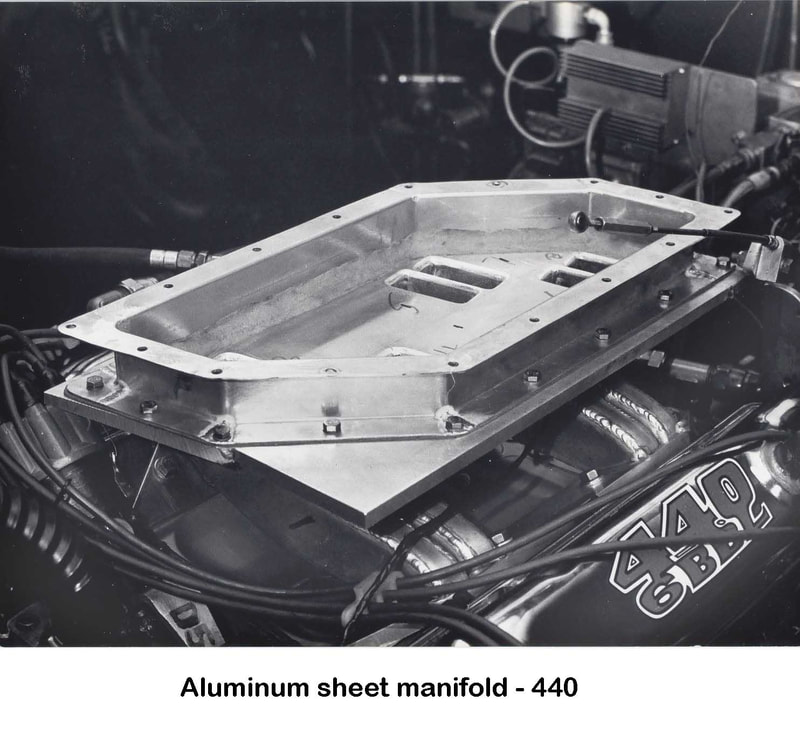

After this bit of entertainment, we went back to work. The ideas from Hoover and myself were endless and your dad got to make most of then happen. Intake manifolds made from sheet metal. Header after header. Oil pans galore. We not only made a half dozen pan configurations but we made numerous spacers to determine the optimum depth. I say we but all I did was draw them up. Your dad had the privilege and honor of making them come to life. As I said above I will attach a few photos of some of his work.

It was a privilege to know and work with your dad. He never hesitated to offer assistance, especially to this newbie engine guy. Sometimes your dad was referred to as the grumpy old man, even by me on occasion. But believe me I said it with love and affection. He was extremely talented and to some extent, unrecognized for these talents. But certainly not by me.

Bob ‘Turk’ Tarozzi

Yes, I knew and worked with your dad Bobby Sykes. Funny the way that came out, Bobby instead of Bob. I cannot remember why but I was first introduced to your dad by Keith as Bobby. And it stuck. I was always a little apprehensive about calling him Bobby because I was the youngster at the time, barely 30, and your dad could have been my dad, around 50, I guess. Before I get into our time together a little background would be in order.

In 1966 I came to Chrysler on a work/study program at the Chrysler Institute of Engineering. I soon made my way into the Race Group where I met and became friends with Pete ‘Hutch’ Hutchinson. I left Chrysler in 1969 and join Hurst to design, build and manage the AMC Javelin NASCAR race team. At the end of the season I decided to stop in California to look for some work. I stopped by Keith Black Racing Engines to see Hutch. At that time, he was working on the Trans Am program after finishing up the Indianapolis project. I’m sure I met your dad at that time but I do not recall him specifically. Pete sent me to All American Racers to interview with Dan Gurney for the upcoming Trans Am program. I got the job and proceeded to design, build and manage the program for 1970. At the end of 1970 I was floating around when I got a call from Tom Hoover, old drag race boss at Chrysler. Apparently, Chrysler had hired Harry Westlake, from England, to design a cylinder head for the then new Chrysler 426 Hemi engine. Engineering in Highland Park Michigan had run the engine with very little success and did not want to continue with its development. Hoover asked me if I would go to Keith Blacks place and continue the development of the Westlake head, designated the D5. Of course, I said yes, I was out of a job after all, and off I went to Southgate. Bob meet Bobby. Long story I know but that’s actually the short version.

Bobby, excuse me if I continue to refer to your dad as Bobby but it’s the way I remember him. He was assigned to me, or vis versa by KB. The problem with the D5 cylinder head was that the valve guides would loosen up after a short time on the dyno. I had a few off-the-wall ideas, but your dad went right to work on the problem. In short order “we” had the problem fixed and where off and running. Which brings me to the dyno. The dyno and the dyno room were really your dad’s domain. Normally he was the main man when it came to “driving” the dyno. But somehow, I never really understood how or why, your dad sensed my desire to the “drive” the nasty beast and taught me what he knew and let me take over the chores almost from the beginning. We worked well together to say the least. The Chrysler program expanded exponentially. We were developing all of the Chrysler family of performance and race engines. The 426 hemi, 440, 383, 340, and numerous versions of the 305. Oh, and we threw in a few Mitsubishi four cylinders for variety. I usually had two of each type ready to go. As a result, we were running engines every day, probably five hours a day. There were several other engine builders that built up the Chrysler packages but your dad and I worked the most together. We, I, had a thing going. I was really into my job, but at the same time I was 30 years old. I lived in Huntington Beach and got hooked on surfing. I would go out in the early am and surf, be back home and ready to roll up to KB’s place by 8:30 or so. To get things moving at KB’s I would call your dad and tell him I was on my way and ask him to get such and such engine warmed up on the dyno and I would be there shortly. I know I wasn’t fooling anyone but he never said a world. Sometimes I would even have sea water still running out of my nose when we started the dyno runs. He would just laugh and off we’d go.

The noise from all these dyno runs became unbearable, especially for the guys working in the machine shop area. I do not know how they got away with it before. Perhaps they didn’t run as often. I thought we should have some sort of an exhaust system to contain the noise. Your dad knew exactly what we needed and how to do it. I sketched it up and you dad fabricated and welded the monstrosity together. I’ll included some photos at the end. For now, let’s just say it resembled two jet engines. But some peace was had in that little corner of Southgate. As I stated we worked on all varieties of the small block, especially the 305 version.

Your dad and Hutch started it with the Indy version, although it was actually 330 as I recall, but it was a small block known as the A engine. Next came the Trans Am 305 package. All the components were run through KB’s place. Then there were a number of them sent over to All American Racers for the Plymouth program and the rest were used for the Dodge program with Aerodynamics. Your dad and Hutch developed the package for the Dodges. This was in 1970. In 1971, during my tenure, came the 305 Rossi NASCAR engine. The Rossi engines were a derivative of the Trans Am package. The TA was carbureted and had a wet sump oil pan. The NASCAR version was carbureted but ran a dry sump oil pan. I specked it out but your dad did the complete build up. Part of the testing was to run a simulated NASCAR race on the dyno. I was shuffled aside for this and KB and your dad took over the dyno room command post. The engine was run at WOT for a gas tank worth of fuel. The engine was then idled to change the fuel barrel and then returned to WOT. A simulated pit stop. I just watched for this event, but your dad and KB enjoyed the hell out of being driver and pit crew. The police came by during the night to watch and then went on their way. A good time was enjoyed by all. Subsequently two 305’s where sent to Mario Rossi, Bill Rossi’s dad.

After this bit of entertainment, we went back to work. The ideas from Hoover and myself were endless and your dad got to make most of then happen. Intake manifolds made from sheet metal. Header after header. Oil pans galore. We not only made a half dozen pan configurations but we made numerous spacers to determine the optimum depth. I say we but all I did was draw them up. Your dad had the privilege and honor of making them come to life. As I said above I will attach a few photos of some of his work.

It was a privilege to know and work with your dad. He never hesitated to offer assistance, especially to this newbie engine guy. Sometimes your dad was referred to as the grumpy old man, even by me on occasion. But believe me I said it with love and affection. He was extremely talented and to some extent, unrecognized for these talents. But certainly not by me.

Bob ‘Turk’ Tarozzi

RSS Feed

RSS Feed